Electrically conductive adhesives

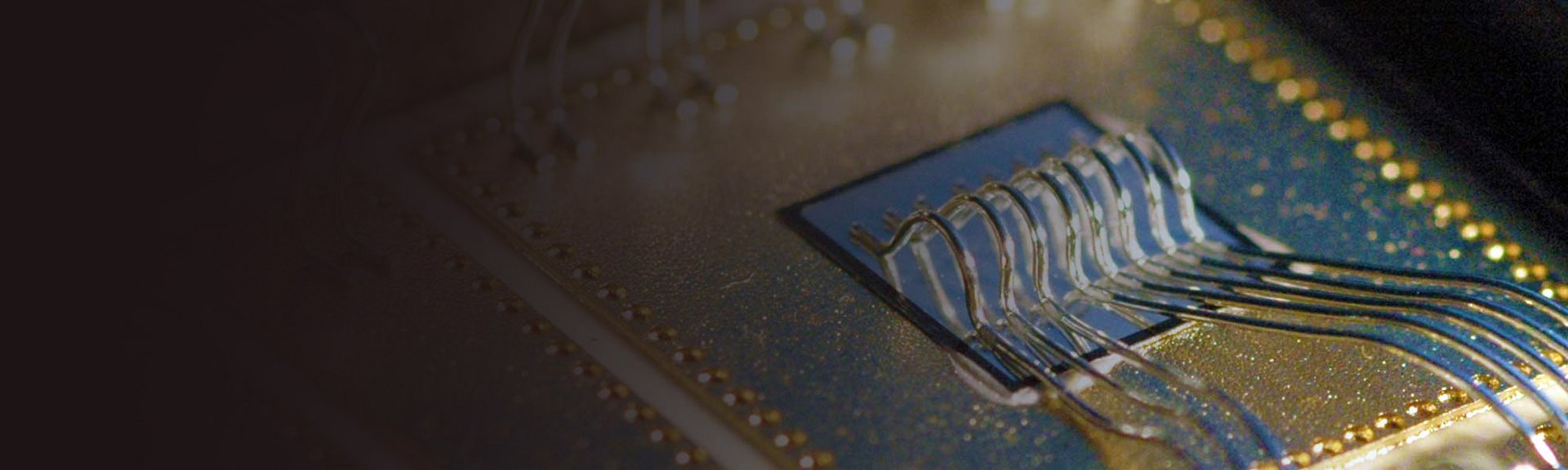

Electrically conductive adhesives are employed in integrated circuit packaging to provide a permanent mechanical connection of components and at the same time to enable electrical contact between them. In many cases, bonding is an alternative to the usual joining techniques, such as soldering or sintering.

How is an adhesive able to conduct electricity?

An adhesive that conducts electricity? How is that possible? Amazingly simple! In order to transform a Polytec EP into a Polytec EC, inorganic, electrically conductive fillers are added to the resin base. It is only through the addition of these metallic fillers and their mobile electrons that the material becomes conductive. Silver is one of the most common fillers used, due to the long-lasting reliability of the electrical connection.

Electrically conductive adhesives are characterized by their specific volume resistivity, which serves as a measure of their lateral conductivity. Typically, the volume resistivity of silver-filled adhesives is of the order of magnitude of 10-4 Ω∙cm.

Electrically conductive adhesives for your application

For many years, conductive adhesives have offered a proven method for providing contact between components, whether in microelectronics, automotive electronics or the photovoltaic industry. Such applications can be found in both small batch sizes and in mass volumes.

Electrically conductive adhesives are used in the following areas:

- Microelectronics: chip assembly, circuit board assembly

- Automotive electronics: providing contact between various current-carrying components

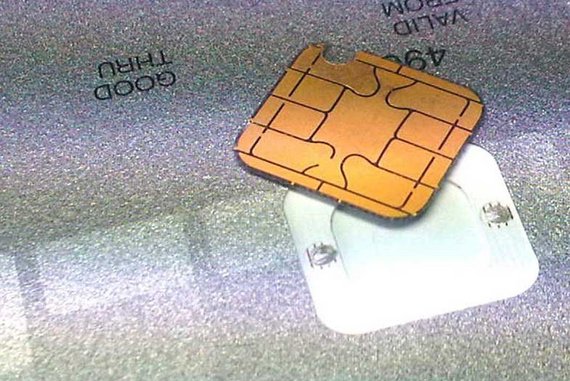

- Smart Cards: providing contact between the chip module and the RFID antenna

- Photovoltaics: providing contact between cell connectors

- Electrical engineering: shielding of electromagnetic fields, dissipation of electrostatic charge

Advantages of conductive glues

We as a manufacturer, live and experience electrically conductive bonding as a reliable alternative to welding or soldering. The specialty is, difficult material combinations can be established, without even having to alter the surface or structure of the substrate. Since many of the Polytec PT adhesives can be cured at moderate temperatures or simply at room temperature, joined components are subjected to far less thermal stress than is the case when soldering. Depending on the product properties, an electrically conductive adhesive can be applied professionally by means of dispensing, jetting, screen printing or stamping.