Thermally conductive adhesives for your electronics

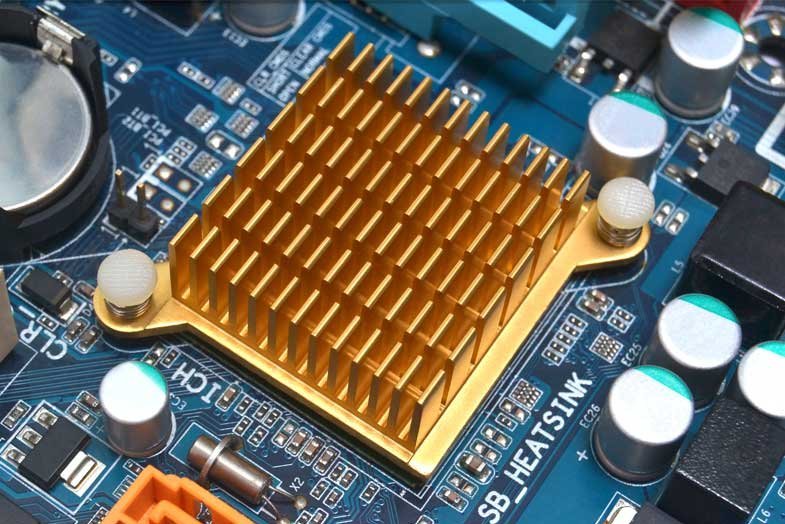

In electronics, thermally conductive adhesives are generally used, e.g. in microelectronic circuits, to attach components to heat sinks or heat-dissipating substrates or to encapsulate sensors and thus protect them from environmental influences. To ensure high structural strength, and thermal and chemical resistance simultaneously, these adhesives are preferably formulated based on epoxy systems. The connections are both force-fit and thermally conductive and therefore offer an interesting alternative to soldering, welding or mechanical joining. In contrast to conventional connection techniques, adhesive bonding also permits difficult material combinations and avoids undesirable effects such as deformation or discoloration. Another advantage is the very low process temperatures, combined with a low level of process complexity. Even in power electronics, bonding power modules with electrically and thermally conductive adhesives is an established alternative to conventional connection methods.

Thermally conductive adhesives from Polytec PT are based on epoxy resin systems that are fused with thermally conductive fillers. You can choose from metallic fillers such as aluminum, copper or silver (the latter, if an electrically conductive connection is required at the same time). However, if the connection must be electrically insulating, ceramic fillers are used, which guarantee both high specific volume resistance and high dielectric strength.

Polytec PT offers an extensive range of thermally conductive adhesives that meet different requirements in terms of thermal conductivity or electrical properties and are also compatible to the different application and processing methods of selected products. In addition to one-component and hot-curing variants, the portfolio also features two-component products that cure at room temperature. The materials can be applied by dispensing, jetting, screen printing or for small series, by manual processing. Variants are available for manual application that can be processed from side-by-side cartridges. The two components are mixed simply by squeezing the components out of the two chambers of the cartridge through a static mixer that comes with the cartridge.

Benefit from our wide-ranging expertise in thermally conductive bonding and potting. A contact, that conducts!

You can also find further adhesives for the requirements of the electronics industry on our partner website: born2bond.bostik.com/de/industries/electronics