Thermally conductive pastes and thermally conductive gap fillers in battery thermal management

Recently, there has been a strong and increasing demand for innovative manufacturing concepts for electric and hybrid vehicle batteries. The design of a battery system made of lithium-ion cells presents special challenges to thermal management. As the performance and durability of the cells depends strongly on their operating temperature, the thermal management system must allow an efficient dissipation of the heat loss, as well as for heat supply in case the batteries are cold. During operation, heat is generated when the system is being discharged due to acceleration, but also when being charged at the charging station or during recuperation of braking energy. Heat delivery and dissipation can be provided in various ways. Liquid-cooled systems have heat exchangers joined to the cells where the cooling medium absorbs the heat and conveys it to an external cooler. The heat transfer is mostly accomplished directly from the cells into a cooled baseplate, where Thermal Interface Materials (TIMs) ensure an optimal thermal connection of the components and compensate for dimensional tolerances.

Structural thermally conductive adhesives ensure both mechanical and thermal connection. They are used to bond prismatic (hard case) cells to coolers or housings or to attach external chillers to frames holding the individual cells, e.g. in hybrid or 48V batteries.

Removable TIMs such as single component non-curing conductive pastes or curing gap fillers are designed to provide thermal connection only, while cells or modules are fixed mechanically to the cooler or a battery tray. They thus allow for repair concepts when individual modules need to be replaced.

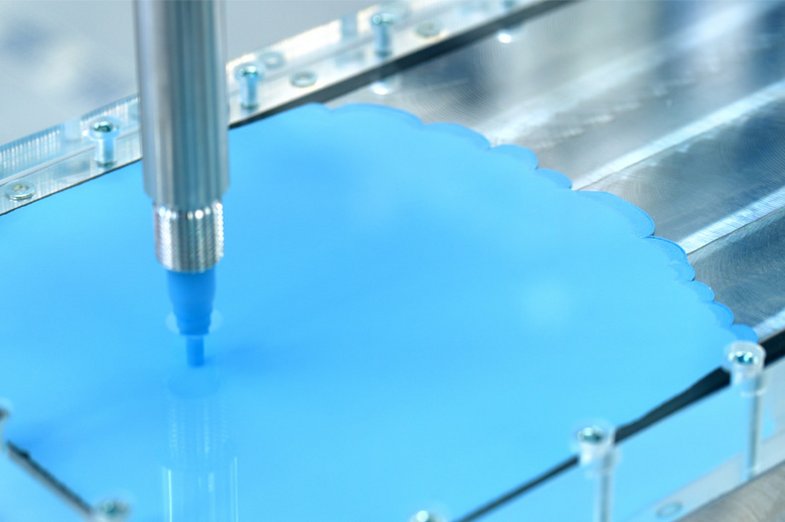

Typically, TIMs are dispensed on one of the components prior to assembling. However, more recent manufacturing processes require TIMs that can be injected into the resulting gap after cell-modules have been attached to the cooling system.

For your application, Polytec PT offers a comprehensive range of thermally conductive adhesives, pastes and gap fillers. Our products are already available in a variety of thermal conductivities and process properties, but can, if necessary, be customized to your requirements.

Polytec PT’s thermally conductive adhesives and gap fillers are only available silicone-free, which eliminates risks for downstream coating, bonding or painting processes.

Likewise, only non-abrasive fillers are used for applications in automated mixing and dosing processes to prevent excessive wear on system components from the outset. Benefit from our extensive expertise in thermally conductive connections.