Thermally conductive adhesives in battery thermal management

Recently there has been a strong and increasing demand for innovative manufacturing concepts for electric and hybrid vehicle batteries. The modern design of a battery system made up of lithium-ion cells, once again poses demanding challenges for thermal management. Since both performance and durability of the cells, and thus of the entire battery, depends heavily on the operating temperature, the thermal management system must ensure efficient dissipation of the heat generated. In operation, heat is generated when the system is discharged due to vehicle acceleration, or when being charged at the charging station or during the recovery of braking energy. The heat supply and heat removal can take place in different ways. Liquid-cooled systems feature heat exchangers that are directly connected to the cells. The cooling medium absorbs the heat and transfers it to an external cooler. The heat transfer usually takes place directly from the cells into a cooled base plate, with thermal interface materials (TIMs) that ensure an optimal thermal connection of the components and compensate for dimensional tolerances.

The advantage of structural thermally conductive adhesives is that they can not only provide a thermally conductive connection but also a mechanical one. Thermally conductive adhesives are therefore very often used to connect e.g. prismatic cells (hard case cells) to coolers or housings or to attach external coolers to frames or battery housings, e.g. in hybrid or 48V batteries. Since the cells should not be exposed to elevated temperatures during operation nor during battery production, only room temperature curing systems come into consideration. Two-component epoxy resin systems, which provide high-strength, aging and impact resistant connections completely without the use of primers, have proven to be particularly useful for bonding aluminum substrates. Depending on the requirements, we can provide high-strength, impact-resistant as well as elasticized systems.

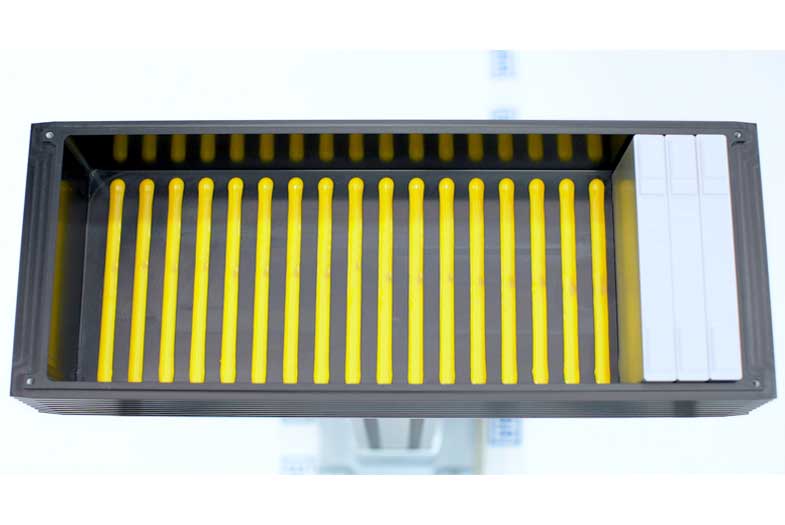

In terms of user-friendly processing, Polytec PT relies preferably on non-abrasive fillers to prevent excessive wear on your mechanical system components. For special applications where resolvability of the thermal bond is required, Polytec PT offers an extensive range of one- and two-component gap fillers. When bonding cylindrical Li-ion cells in plastic cell holders, you can choose from a range of two-component epoxy resins or UV / dual-curing adhesives.