Conductive adhesives for LED contacting

Light-emitting diodes, LEDs for short, can emit light as soon as electrical current flows in the forward direction. Decades of development has led us to the LED light sources as we know them today, these enjoy a widespread popularity, and their numerous different properties allow access to new design possibilities.

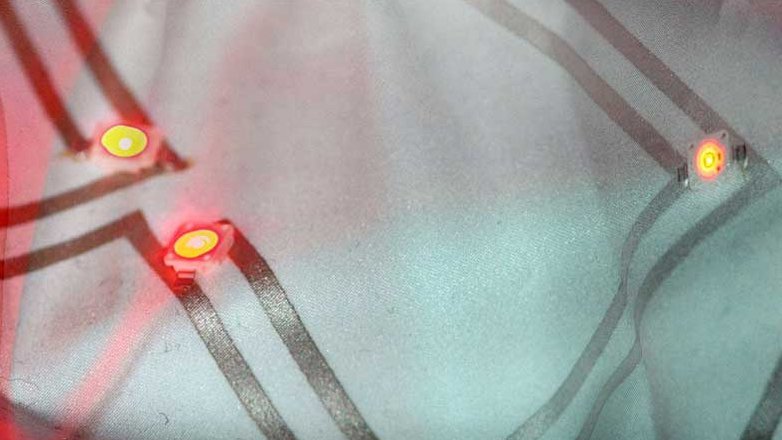

With the introduction of LED technology, bonding is also finding its way into the lighting industry worldwide for many reasons. As a procedural advantage of adhesives, we would like to emphasize the associated low process temperature in comparison to a classic soldering process. A further advantage is the possibility of assembling components consisting of non-solderable material. Ultimately, the challenge is not only to ensure electrical contacting of heat-sensitive substrates, such as plastic, paper or cardboard, which would be destroyed or damaged by the high soldering temperatures, but also to ensure successful and permanent contacting of mostly very flexible substrates. This in turn places very high demands on the flexibility and elasticity of the conductive adhesive. Despite the usual high filler levels, which are indispensable to provide the electrical performance, the adhesive should be able to undergo sufficient expansion and bending, or even movements of all kinds without losing adhesion or electrical contact.

Bonding in combination with LED technology can therefore not only be used in classic lighting technologies, but also allows surprisingly creative designs to effectively integrate light into textiles or packaging, and literally put them in a different light.

Polytec PT has met these challenges and offers you specifically adapted electrically conductive adhesives for various applications in the field of LED contacting, which can cure at low temperatures, offer excellent adhesion and also take flexibility into account.

Polytec PT offers you an extensive range of electrically conductive adhesives suitable for all common application techniques. Starting from conductive silver adhesives for manual application in prototype or sample production up to fully automated assembly processes with adhesive application by dispensing, screen printing, jetting or stamping.

Benefit from our wide-ranging expertise in electrical bonding. A contact, that conducts!

You can also find more products on our partner website: born2bond.bostik.com/en/industries/general-assembly