Thermally conductive adhesive

When used as a joining technique, thermally conductive adhesives fasten components to create a durable mechanical connection, while enabling heat transfer from the warmer to the colder component. Thermally conductive bonding is therefore in many cases an alternative to conventional joining processes such as soldering, welding and screwing.

What is thermal conductivity?

The thermal conductivity refers to a specific rate that describes the heat flow through a sample volume of a material and is measured in W/mK.

Typical values are as follows:

Thermally conductive adhesive: ~0.5 to 5 W/mK

Plastics without additives: ~0.2 to 0.3 W/mK

Glass, ceramics: ~1 to 30 W/mK

Metals, alloys: ~10 to 400 W/mK

Applications for thermally conductive adhesives

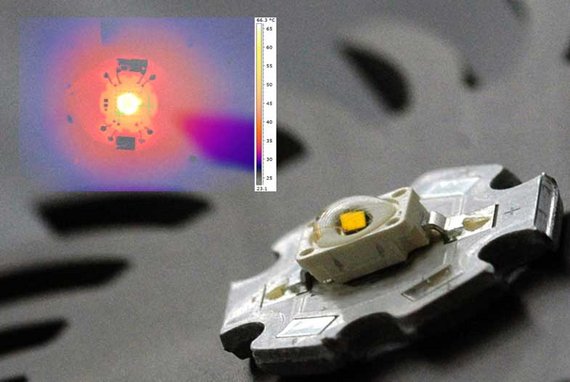

Whether in microelectronics, vehicle or energy technology, good thermal management helps to improve the service life of the end product and thus positively influence its energy efficiency and environmental balance.

Thermally conductive adhesives are used in the following areas:

- Microelectronics: chip assembly, encapsulation, heat dissipation

- Sensor technology: potting of thermal sensors

- Power electronics: assembly of power modules

- Energy engineering: connection of pipes and surfaces in heat exchangers

- Automotive engineering: bonding and casting of battery cells, electric motors and more

Advantages of adhesive bonding

Thermally conductive bonding as an alternative to welding or soldering, it enables joining of many materials, even difficult material combinations such as copper and aluminium. These adhesives are gap-filling, thermally conductive over large areas and resistant towards water, oil, and gases. Given that the adhesives are cured at room temperature or at moderate temperatures, neither mechanical stresses nor unwanted distortions or discolorations are generated.

Thermally conductive pastes for temporary connections

In the event that thermally bonded components must later be separated or replaced without being damaged, we offer pastes with thermal conductivities of 1-3 W/mK and application-oriented processing properties.