UV glues for your electronics

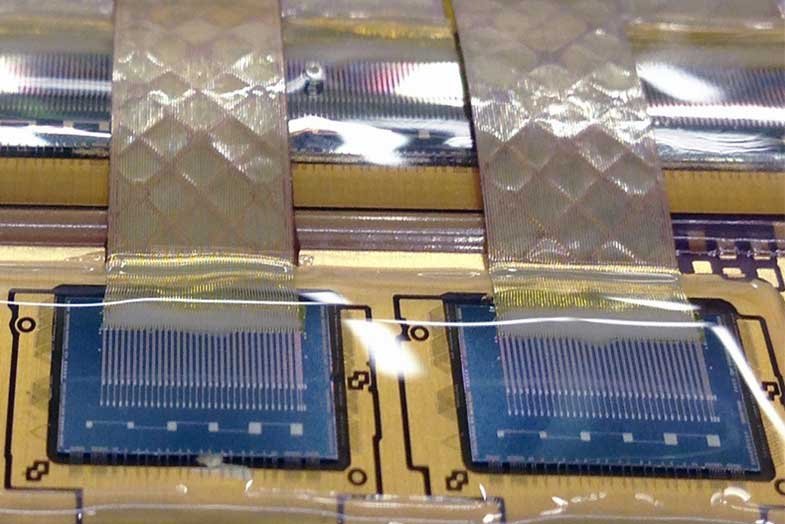

As they cure within seconds, light-curing adhesives are preferred when a large quantity must be manufactured in short cycle times. This is in fact the case in many areas of electronics manufacturing. These adhesives are suitable for a wide range of temperatures and, thanks to their chemistry, guarantee fast and reliable UV curing. With regard to these properties, UV-curing systems are ideal products, for example in the encapsulation of electronic components to protect them from environmental influences, for wire fixation and vibration protection, or for the encapsulation of connectors and switches. With the help of further indivual properties of the UV adhesive, opaque materials can be joined just as reliably. The areas of application are numerous including but not limited to sealing, bonding, fixing, potting and coating in the field of microelectronics, optoelectronics, electrical engineering as well as in the automotive sector.

An essential parameter for successful curing is the intensity of the light source used. Subsequent introduction of heat can often result in post-crosslinking, which can change the mechanical properties. Curing is also influenced by the ambient temperature and humidity and should always be taken into account in a manufacturing process with regard to seasonal fluctuations.

Polytec PT offers you a wide range of UV-curing adhesive systems for a variety of applications. This includes both purely UV-curing acrylates or epoxies, as well as dual-curing systems that have a second curing mechanism and can therefore be cured in shadow areas. For optical quality control, we also offer our fluorescent adhesives. Our products are ready-to-use for you and easy to use. If the products are stored below room temperature, ensure that they are brought to the operating temperature before use.

Benefit from our many years of expertise in UV bonding. A contact, that persists!

You can also find further adhesives for the requirements of the electronics industry on our partner website: born2bond.bostik.com/de/industries/electronics